Blog

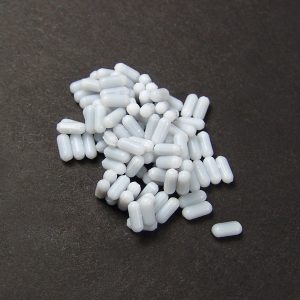

Magnetic Stir Bars

Published: January 13, 2025

While the small white tubes are undoubtedly the most familiar, stir bars come in a variety of shapes, sizes, and magnetic compositions. The magnetic materials contained within these stir bars greatly impact their performance and an understanding of these materials is necessary to select the optimal stirring element.

If one were to open the non-reactive coating of a stir bar, they would likely find one of three materials: alnico, samarium cobalt, or neodymium, all of which have excellent magnetic properties. The most common stir bar material, alnico, is an alloy of aluminum, nickel, and cobalt. This material has a high Curie temperature, allowing for it to be used at temperatures exceeding 400°C to 500°C, depending on the grade. Care should be taken during storage since its low coercivity will allow it to be demagnetized if subjected to an opposing magnetic field.

Neodymium magnets are created from an alloy of neodymium, iron, cobalt, and boron. Though they are useful only at temperatures below 150°C, they have the highest magnetic field strength of any known material and will provide powerful coupling with a magnetic stirrer. Due to their strength, these materials have become ubiquitous in various electronics. For applications that do not require high temperature operation, this material offers unbeatable performance.

Samarium-Cobalt magnets, though a bit weaker then neodymium, are far stronger than alnico and can be used at temperatures as high as 350°C. For applications that require high torque and high temperature performance, this material offers an excellent mix between the thermal performance of alnico and the magnetic performance of neodymium. For this reason, it is quite popular as a stir bar component. One notable downside, however, is the unpredictable cost due to its high cobalt content.

The magnet inside of the stir bar is only half of the equation. The non-reactive encapsulation is what transforms a spinning magnet into a stir bar. The curved ends on a common stir bar help to prevent it from standing on one end when lowered into the container. Many stir bars come with spin rings around their centers that decrease the friction against flat surfaces, increasing life and magnetic tracking ability. Other devices come with pill shaped forms to more closely follow the contours of curved containers or octagonal cross-sections to generate a maximum amount of turbulence. Other stir bar designs use even more exotic shapes to promote higher efficiency mixing.

Analytical Sales and Services is ready and able to support chemical research by providing two varieties of stir bars that will help transform your test tubes into powerful micro-sized batch reactors. The first offering comes in two sizes with a stainless steel core that has been made ferromagnetic through special mechanical processing. The stainless steel core and the parylene coating allow the user to generate high turbulence in a compact non-reactive package.

The newest model is a PTFE coated 5mm x 2mm alnico stir bar (with other sizes available upon request). These stir bars are usable at temperatures up to 200°C and allow for high torque operation. Compared to the parylene coated fleas, the PTFE coating on these devices allows for the same high temperature operation with a much broader range of chemical compatibility.

As a trusted and reliable supplier to the biotech and pharmaceutical industries, Analytical Sales and Services is well accustomed to fulfilling the needs of niche applications. If you require dimensions or compositions outside of the options listed above, do not hesitate to reach out. We have an extensive variety of potential sizes, shapes, and magnetic materials to promote ideal mixing regardless of your analyte’s viscosity. Should your stir bars lose their magnetism, we may even be able to supply a re-magnetization tool to restore your devices to full capability. With Analytical Sales’ line of stir bars, inadequate mixing will never stall your workflow.