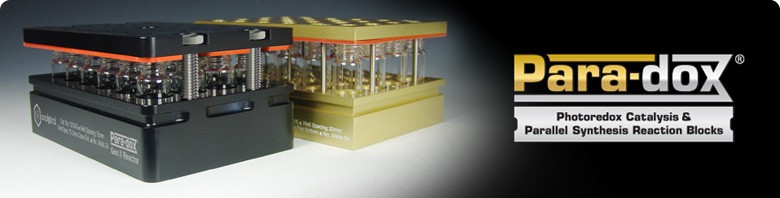

Para-dox® Aluminum Reaction Blocks

A successful approach to high-throughput reaction screening requires the best tools available. Our comprehensive line of photoredox catalysis and parallel synthesis reaction blocks is exactly what you need. Designed specifically for high-throughput screening (HTS) applications, the SBS (SLAS/ANSI) format allows for use in any industry standard automation application. Within each reaction block are silicone mats for compression sealing, as well as PFA films to keep glass vials (your samples) from sticking to the silicone mats during heating. This sealing strategy has resulted in our reaction blocks being validated to have less than 5% solvent loss, even with prolonged heating.

Para-dox® reaction blocks:

- Useful for generating compound arrays (medicinal chemistry)

- Useful for conducting screening reaction conditions

- Can be used on tumble stirrers / hot plate stirrers / robotic platforms

- Can easily be used in a glovebox

- Use with our pre-loaded vial trays in both standard and micro sizes (suggested for quick and easy loading)

We also offer a wide array of accessory items, providing options for a variety of application requirements.

Temperature Controlled Reactors

Analytical is pleased to offer the new Temperature Controlled Reactors (TCRs). The TCR is a 24 or 48-position fluid-filled reactor that keeps temperature consistent...

Micro (50µL, 4x21mm Glass Inserts)

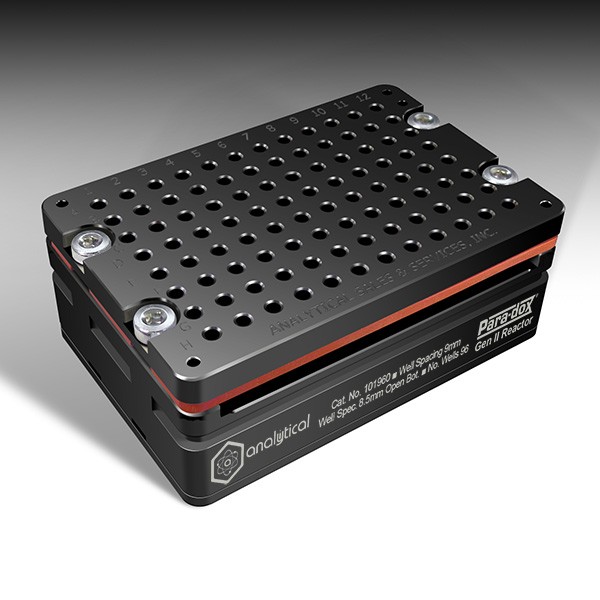

Para-dox® 24 and 96 position reaction blocks for Photoredox Catalysis applications. Use with 4x21mm glass inserts.

Standard (1mL, 8x30mm Glass Inserts)

Para-dox® 24 and 96 position reaction blocks for Photoredox Catalysis and Parallel Synthesis applications. Use with 8x30mm glass inserts.

HPLC Vials (2mL, 12x32mm)

Para-dox® 48 position reaction blocks for Photoredox Catalysis and Parallel Synthesis applications. Use with 12x32mm glass vials.

1 DRAM Vials (4mL, 15x45mm)

Para-dox® 24 position reaction blocks for Photoredox Catalysis and Parallel Synthesis applications. Use with 15x45mm glass vials.

2 DRAM Vials (8mL, 17x60mm)

Para-dox® 24 position reaction blocks for Photoredox Catalysis and Parallel Synthesis applications. Use with 17x60mm glass vials.